While some Santa Clarita Valley residents are dusting off their sewing machines to help fill the shortage of much-needed personal protective equipment, or PPE, for health care workers, others are getting creative with their 3D printers.

Valencia residents Leila and Kevin Rosenberger began by 3D printing masks with the G-Code file needed to print the design from A.J. Apone, who started The Mask Initiative, and they soon decided to switch gears.

Getting the idea from an article, the Rosenbergers switched to printing ear protector straps, which help those wearing face masks with elastic to either prevent their ears from getting sore or to hold the mask in place if the elastic is too stretched out.

“I can print a single full face mask in about 30 hours or I can print five of these little widgets in 90 minutes,” Kevin said.

Leila took to social media, and they quickly received hundreds of requests. Now, they’ve enlisted the help of their son, who also has a 3D printer, to keep up with the demand.

“It’s not really about any one person — it’s a crowdsourcing thing,” Kevin added. “People are trying to do whatever they can do (to help). I just happen to have a printer.”

“I think that our community really has come together in this time, and this is just one of many examples,” Leila added. “We’re happy that we’re in a position to be able to help … So, we will continue to do it until there’s no longer a need.”

Banding together

Groups like Project 691 Robotics, an SCV high-school robotics team, are banding together with other FIRST Robotics students, college engineering students, makers and professionals to create a 3D-printing network.

“The thing we’re focusing on is just making sure that our first responders and the people on the front lines have what they need here in California,” Project 691 coach Aaron Dolgin said. “We still haven’t reached our peak yet, so we’re making sure that the hospitals have what they need to treat (patients).”

SoCal Makers COVID-19 Response Team set up a GoFundMe to assist in raising funds for the project, already nearing $12,000 as 100 volunteers with 50 printers work to print face shields and other PPE.

They’ve produced more than 4,000 medical-grade face shields, 3D printing the frame and using old projector transparencies to create the shield.

“Overhead projectors really are not used anymore, and they’re just collecting dust, especially when there are no in-person classes happening,” Dolgin said.

Working with a transparency manufacturer in New Jersey, they were able to purchase 4,000 at a discounted rate, but as they continue making shields, they’ve begun contacting school districts to gather any they may be willing to donate.

The shields have been sent to health care workers across the country, including Henry Mayo Newhall Hospital, which has received 100 shields as well as 100 ear protectors.

“The shield allows them to maybe not have to replace their masks so often,” Dolgin said. “And, the really cool thing about these face shields is that they can be reused and cleaned very easily.”

The group is expecting to deliver 10,000 face shields by the end of April, “which, since this has been growing so rapidly, should be definitely achievable,” Dolgin added.

Reusable masks

Similarly, Travis Marg has enlisted the help of his son, Tyler, and dad, Edward, to set up their own operation in the garage of their Newhall home, which they’ve called 1st Responder Masks.

Starting with only one printer, they showed the newly designed mask to a captain at the Los Angeles Police Department, who was excited about them, as they are reusable, Marg said.

“You can wash them down and put a new filter in, so it’s kind of like, one mask, one first responder,” Marg added.

Seeing the need, the LAPD sent a helicopter to the Santa Clarita Valley Sheriff’s Station to pick up the first batch of masks as soon as they were ready, then distributed them from there to other first responders or health care workers in need.

Since then, there have been several helicopter deliveries, along with a number of squad cars making frequent trips to the Margs’ home.

While the process was slow at first, as it took almost four hours to print each mask, they quickly decided to scale up their operation and purchase more machines, also starting a GoFundMe to assist with funding.

“We have 12 printers printing at one time in our garage right now — it’s a lot,” Marg said. “And, we’re getting close to about 65 a day of these masks going out.”

In about a month, they’ve been able to make approximately 500 masks, which have been distributed to first responders across L.A. County.

“It’s more labor-intensive than I thought it was ever going to be, though,” Marg added.

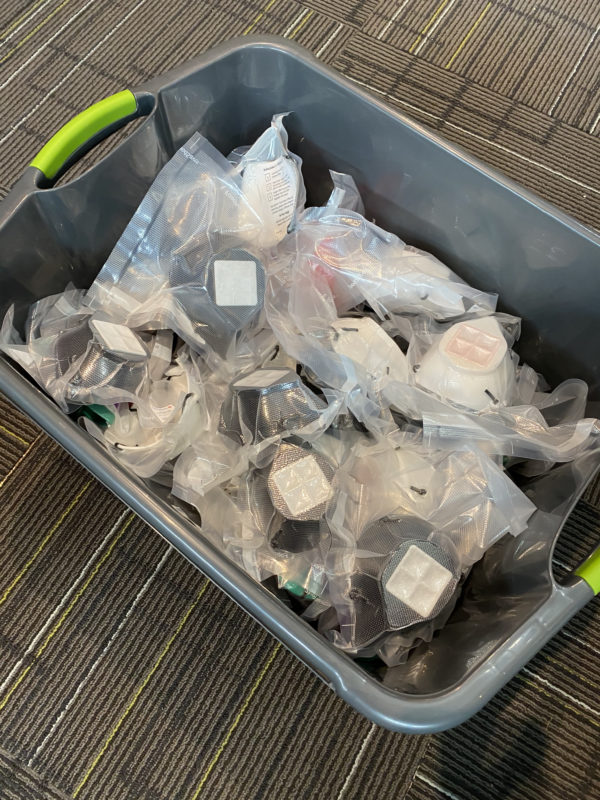

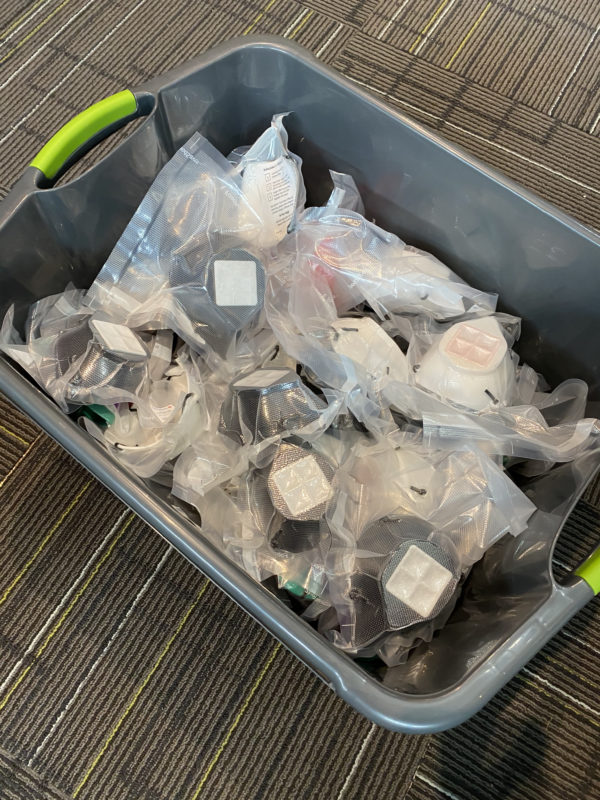

After each mask is printed, the Margs cut hospital-grade, Hepa UV-C air filters that typically go into air conditioning units. Those are then doubled up and make the filter for each mask, and more than a dozen replacements are included with each mask.

“We also make sure they’re sanitary, so we vacuum seal them (in bags) and put the instructions in there,” Marg said.

After the Margs are done with the printers, they plan to donate them to schools in the SCV. “We’ve already contacted all the schools, and they’re excited.”

For more information on the Rosenbergers’ ear protectors, email Leila at [email protected].

To hear more about SoCal Makers COVID-19 Response Team, visit socalcovidresponse.com.

For more on 1st Responder Masks, visit facebook.com/1strespondermask.